About the Case Study _

Onsemi’s products are used across a wide range of industries and are manufactured in dozens of factories around the world. For each component or batch, a data record is maintained that tracks when, where, and how it was produced or tested. Given the number of factories and the volume of parts manufactured daily, the resulting data load is massive. These records are essential for engineers performing analysis and other technical processes – and they require robust and efficient storage and management.

The original system used for data storage and management had become insufficient over time, prompting the need for a modern solution that could meet increasing demands.

Onsemi partnered with Edhouse to develop a new system. Following an initial analysis in 2016, we began developing Dataport, a custom web application built from the ground up. It runs on Linux servers, is built in Java using the Spring framework, and uses an Oracle database. Data was initially stored on Onsemi’s internal servers but has since been migrated to an Amazon cloud-based solution, as originally planned.

Over time, a number of smaller associated applications have been developed alongside Dataport. These support functions such as data migration, transformation, and translation across various required formats.

For Onsemi, the new system has delivered simpler and clearer data availability, data management, and above all greater scalability and flexibility when adding or changing production facilities or entire factories that need to be newly integrated into the overall data system or reflect their changes.

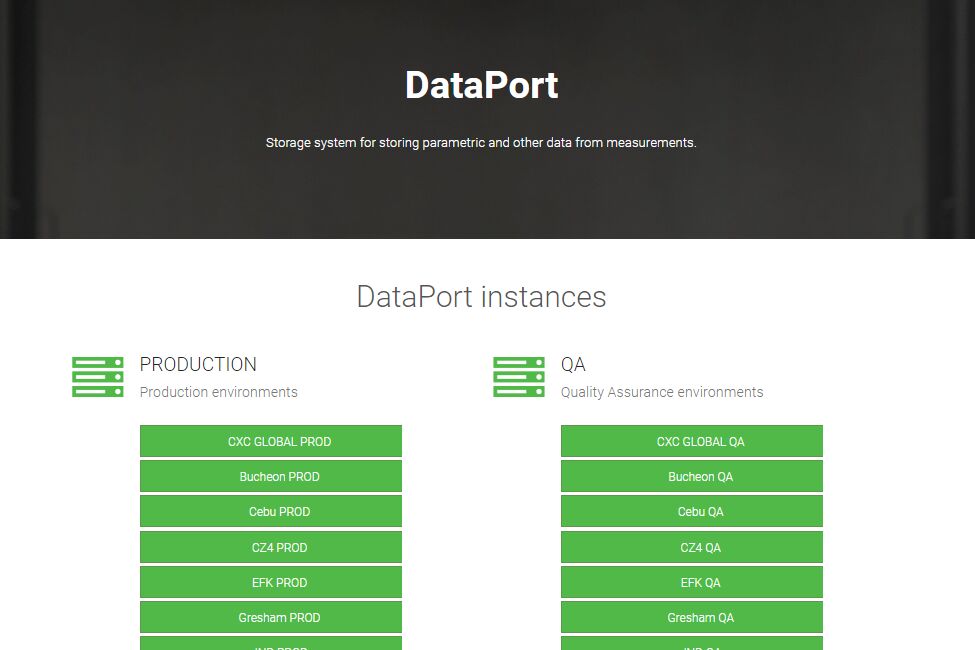

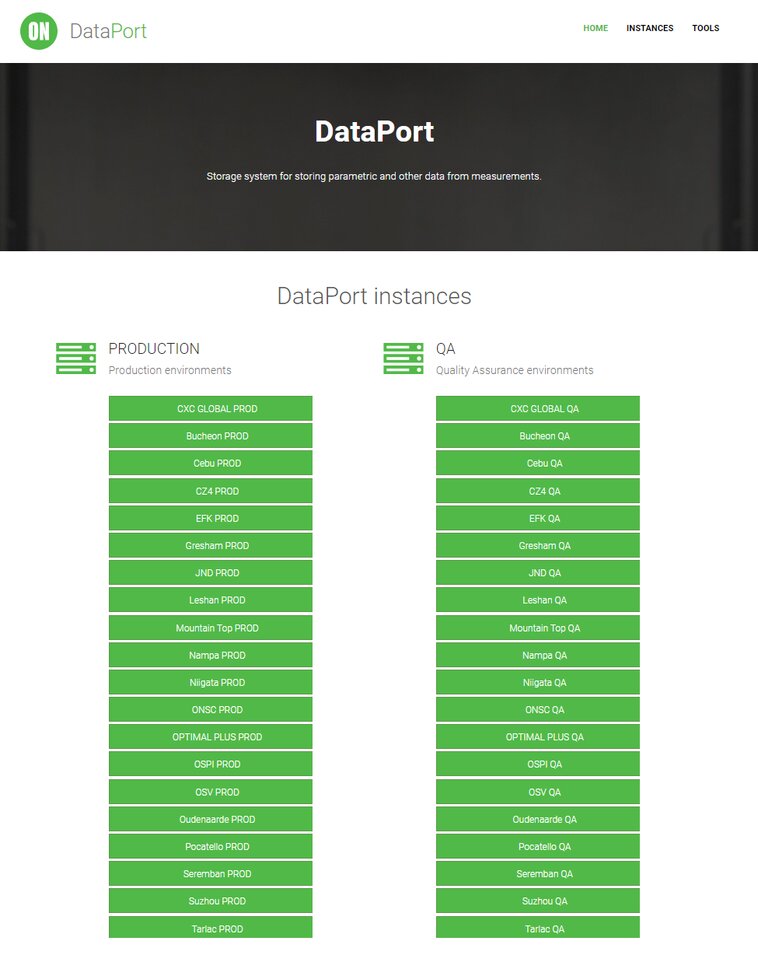

Today, approximately 20 production instances of Dataport are deployed worldwide, each managing data from factories in a specific region. We continue to maintain and enhance both Dataport and its supporting applications in close collaboration with Onsemi, adapting to evolving needs and requirements.

DataPort App